Dmg Lasertec 65 3d Ccat

Os x dmg vs pkg. The standard pkg and the seemlingly standard (but not) dmg. The pkg option will build a standard pkg installer file, which will install with any system that can install pkg files. The dmg option will build a standard dmg disk image file, with the payload of the installer as contents. On its own, however, this dmg cannot do anything. Usually the pkg seems to be already compressed since the dmg doesn't reduce the file size much if any. Example: MonoFramework-MDK-2.10.61.macos10.xamarin.x86.dmg is 119,242,061 bytes (119.2 MB on disk) MonoFramework-MDK-2.10.61.macos10.xamarin.x86.pkg is 119,979,719 bytes (120 MB on disk) A savings of 737,658 bytes, or 0.6% of the original file size. Jul 16, 2006 The.pkg file is created using the PackageMaker of Mac OS for creating the installers. #2.dmg is a disk image, and a.pkg is sort of like a zipped file. #3 DMG:. Disk image format, like ISO, etc. Is not an installer, just a way to store files.

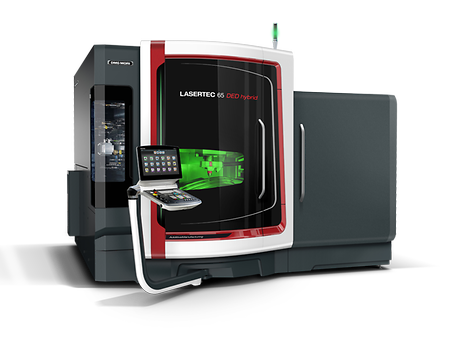

CCAT structured light scanning — with standalone pivoting turntable or on-machine capability DMG MORI LASERTEC 65 3D hybrid (laser deposition welding & milling) GOM ATOS Triple Scanner with 5108 ScanBox (owned and provided by the State of Conn.). Solutions for higher accuracy and shorter deliveries in die & mold making from DMG MORI die & mold professional team. Search by workpiece. LASERTEC 65 3D hybrid. Add/subtract material with DMG Mori LASERTEC 65 3D5 hybrid manufacturing 5-axis machine; Controlled atmosphere builds with Optomec 850R LENS system using multiple hopper powder metal feeds (35x59x35 inch environment) ProJet 5500X with multi-jet 3D printing for plastics (750X750X890 DPI resolution) Count on CCAT. Fusion of Laser Metal Deposition and 5-axis Milling The LASERTEC 65 3D is a hybrid solution that incorporates the additive manufacturing function into a 5-axis machining center. Combining laser metal deposition and milling processes on one machine, the LASERTEC 65 3D demonstrates outstanding performance in various applications, such as machining of complex-shaped parts for aircraft and medical.

Flexibility through combination of additive and milling machining process for 3D-parts in finished quality

- The laser head is handled by a fully automatic shuttle - without manual intervention

- 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent from direction of laser deposition welding

- Full 5-axis milling machine in rigid monoBLOCK-design with < 12 m² footprint

- Process monitoring and adaptive process-control (Closed Loop)

- User friendly and specifically developed software with operator-orientated user interface and CELOS integration

Process monitoring for highest process safety and quality management

- Continuous measuring and monitoring of the laser buildup process as well as automatic regulation of the laser power in real-time for homogeneous part qualities

Siemens NX: Complete Hybrid CAD / CAM – Module for additive and subtractive programming

Dmg Lasertec 65 3d Ccat 3

- One software package for the complete process chain (design, additive process, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine and movements for collision prevention

- Shorter time-to-market due to completete integrated PLM software integration

High-performance additive manufacturing of metallic 3D-parts

- Laser head integrated in the headstock for higher building volume and more additive performance

- 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent of direction of laser deposition welding

- Dedicated additive solution for prototypes, small-series, repair and coating

AM Assistant for the best process reliability and comprehensive traceability

- Integrated thermal imaging camera for observation of the whole working area, adapive process control and constant monitoring of the working distance

- Powder feed rate sensor as well as automatic powder calibration.

- AM Evaluator for visualisation of the relevant process data (e. g. meltpool size, powder mass flow) as a digital 3D-model as well as in the chronological sequence

Dmg Lasertec 65 3d Ccat 1

Siemens NX: Hybride CAD / CAM – Module for additive and subtractive programming

Dmg Lasertec 65 3d Ccat X

- One software package for the complete process chain (design,

- additive machining, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine and movements for collision prevention

- Shorter time-to-market due to completete integrated PLM software integration